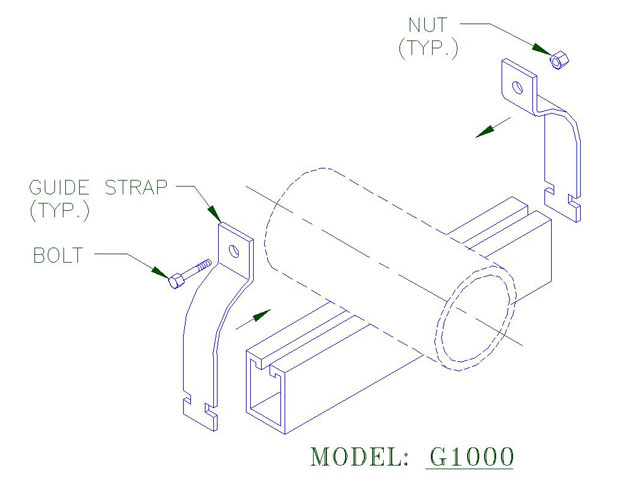

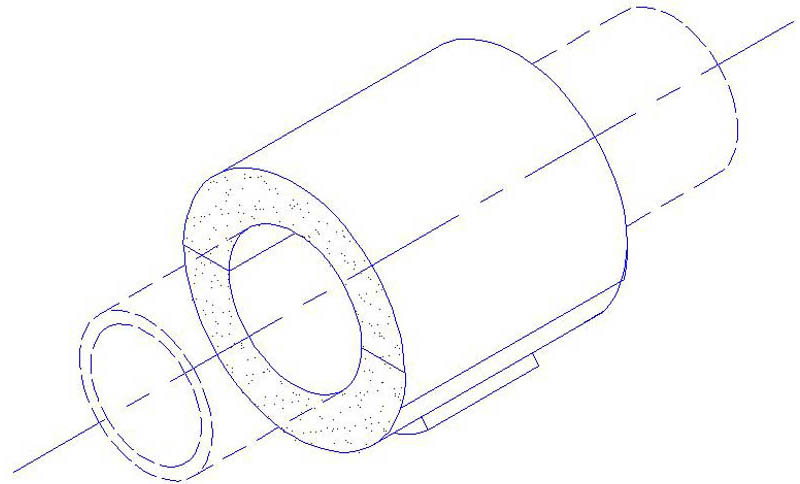

Installation Steps

Model G3000 Installation Instructions

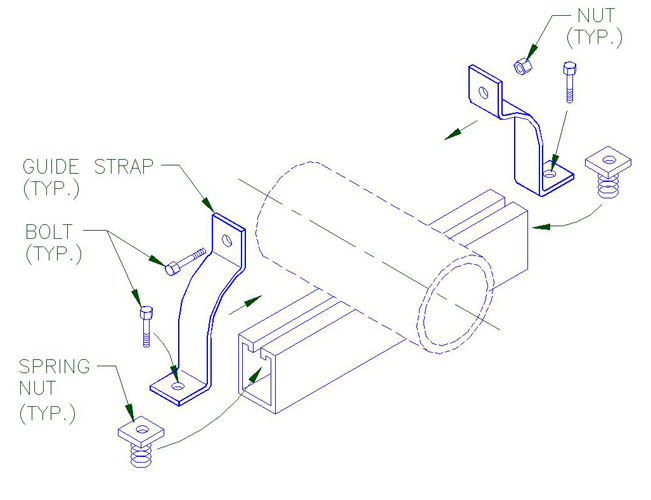

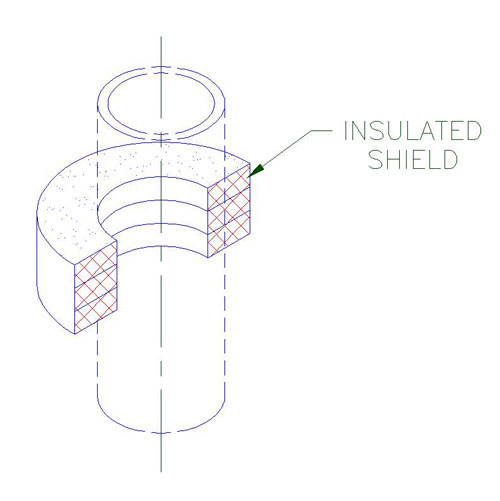

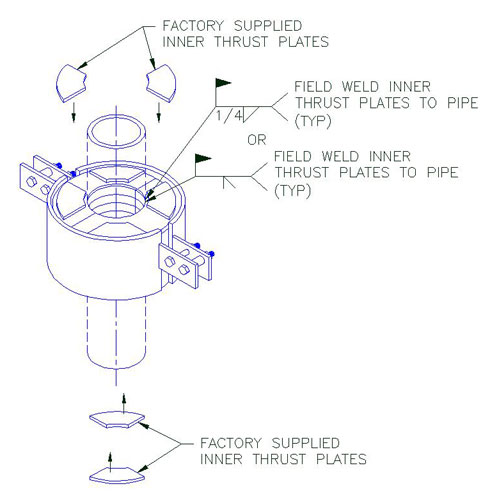

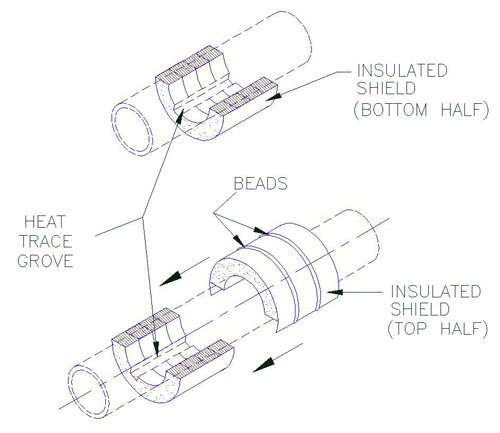

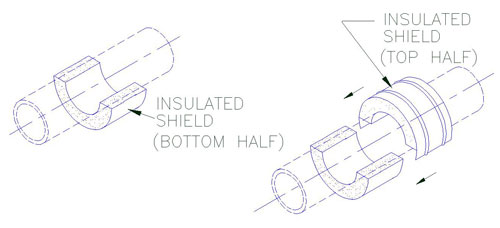

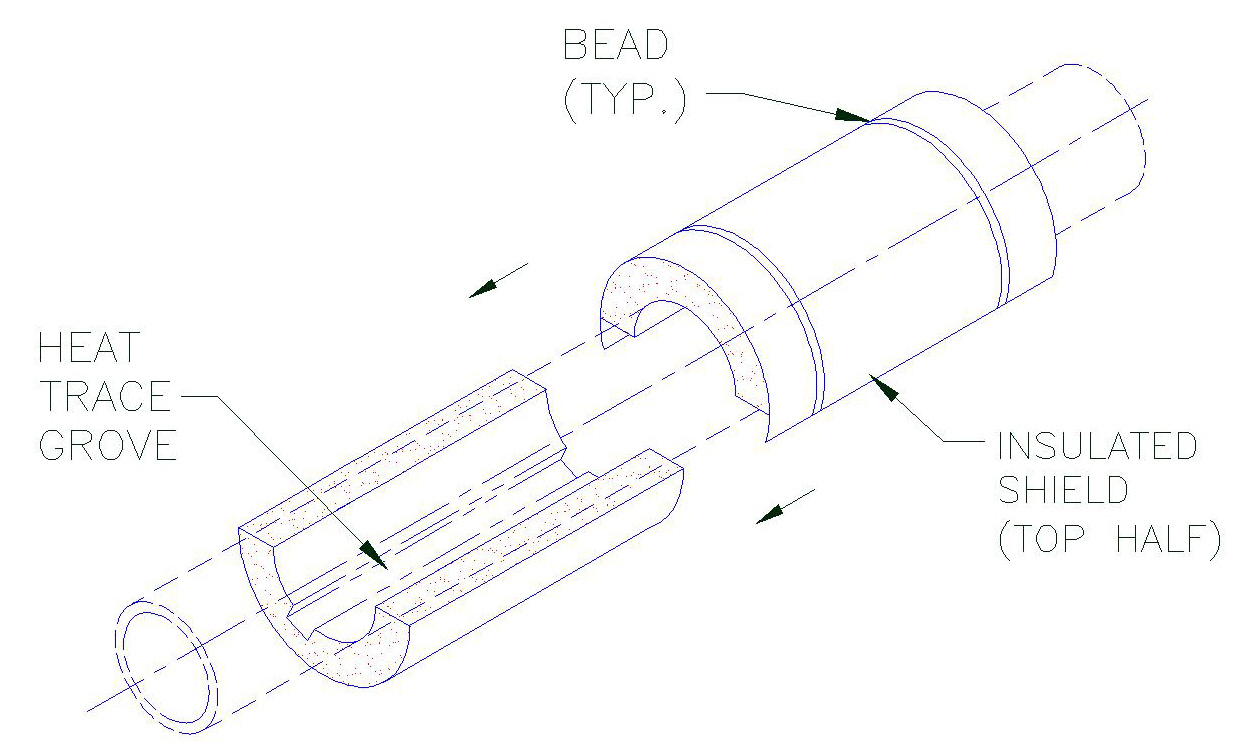

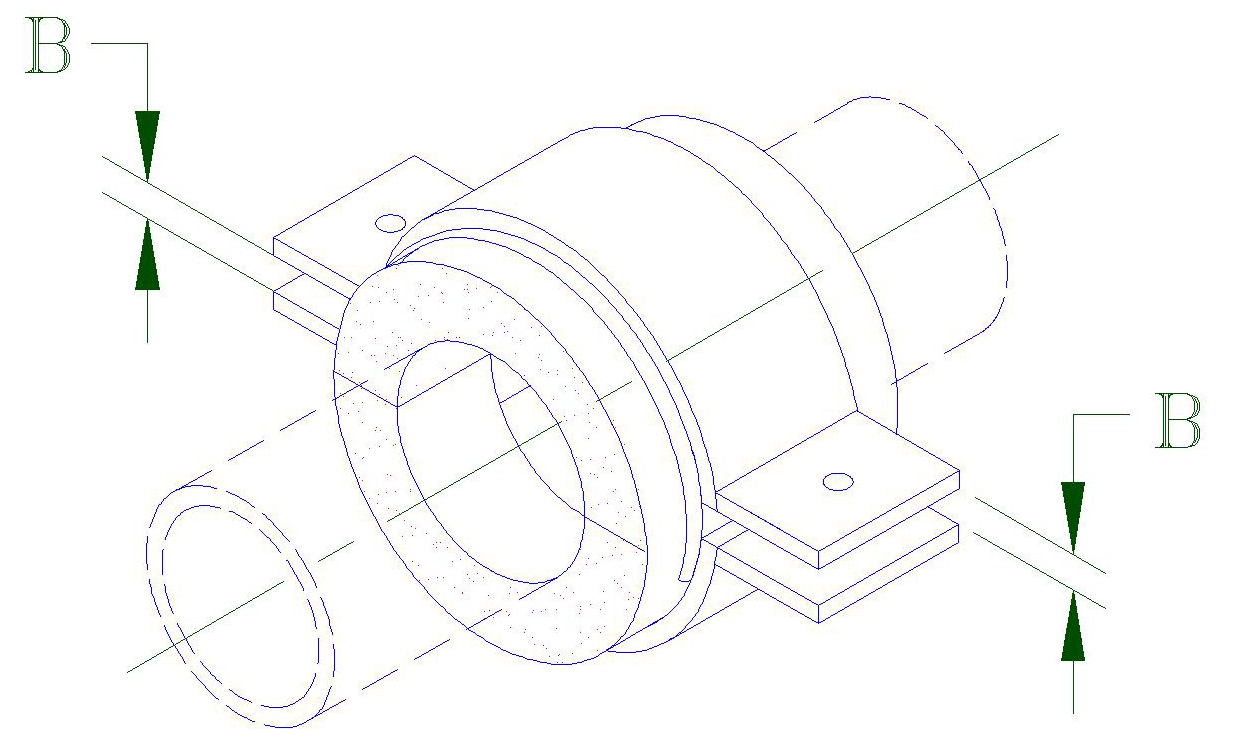

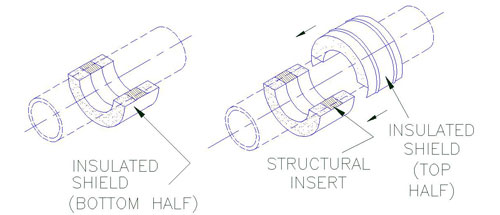

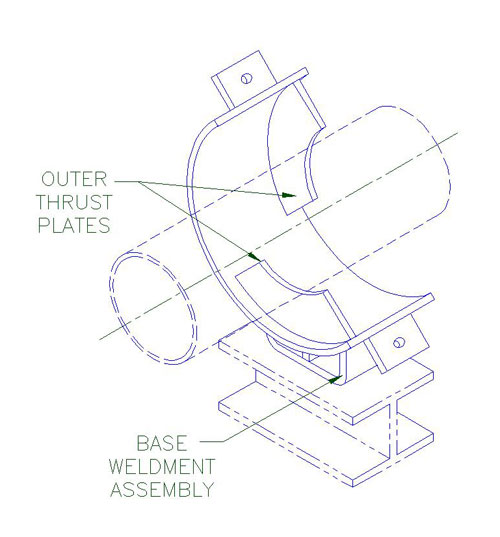

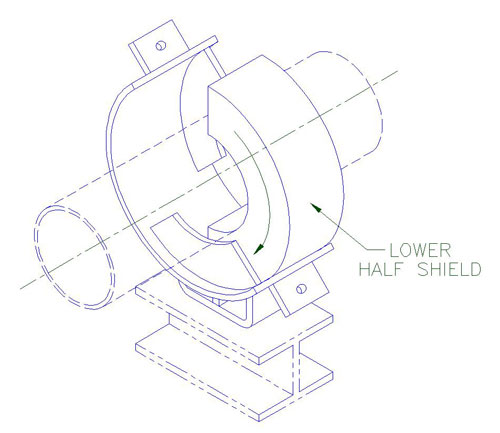

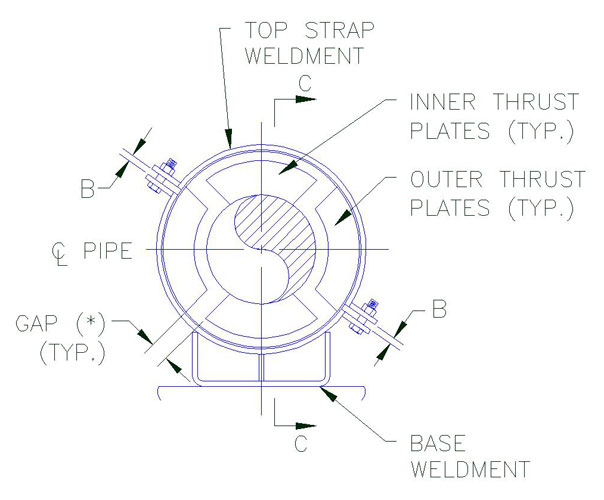

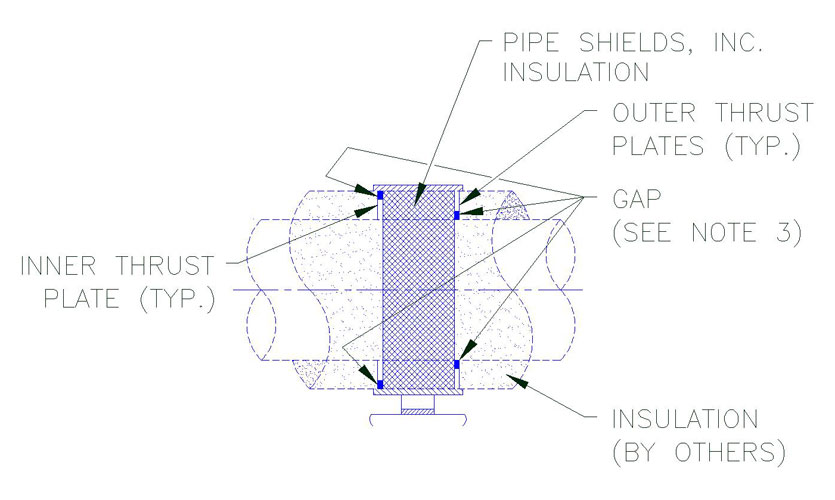

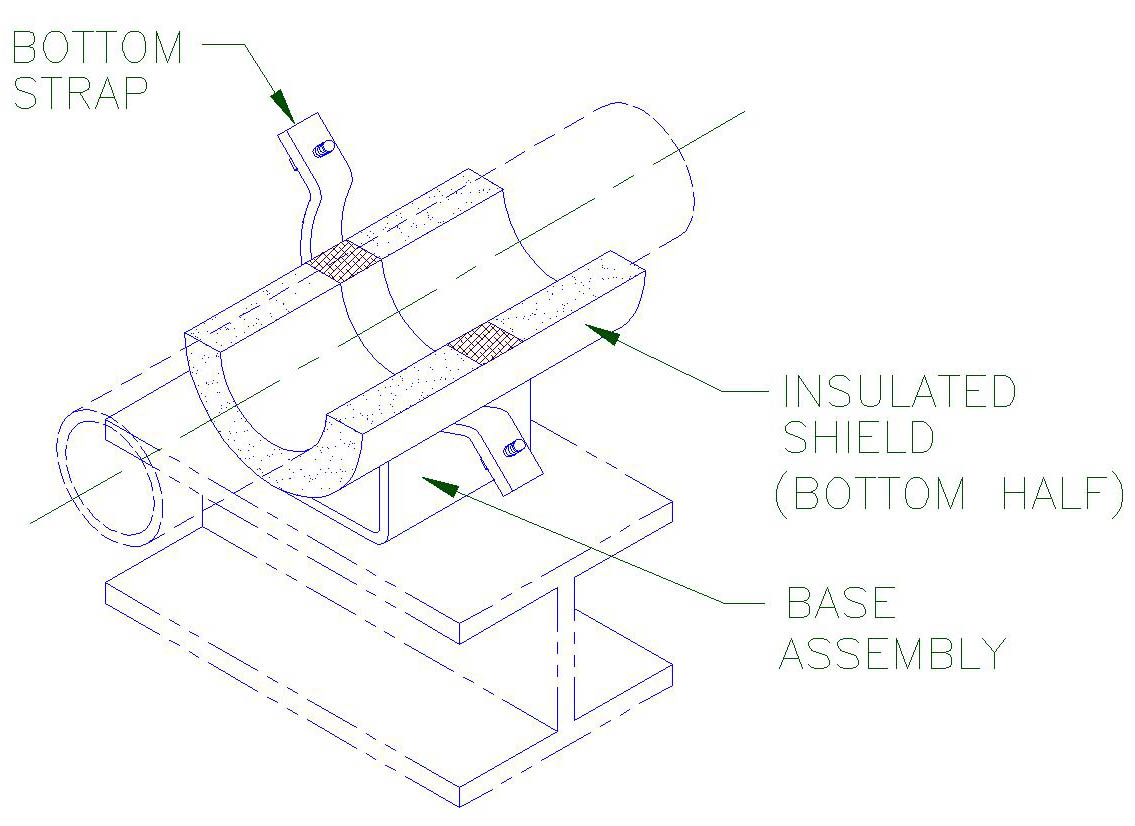

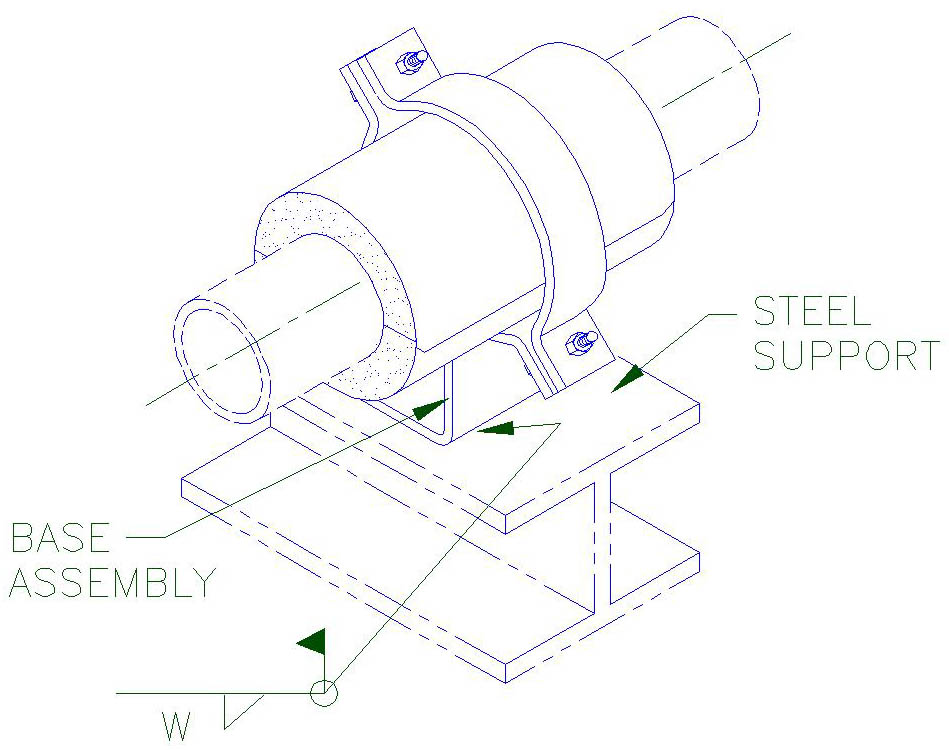

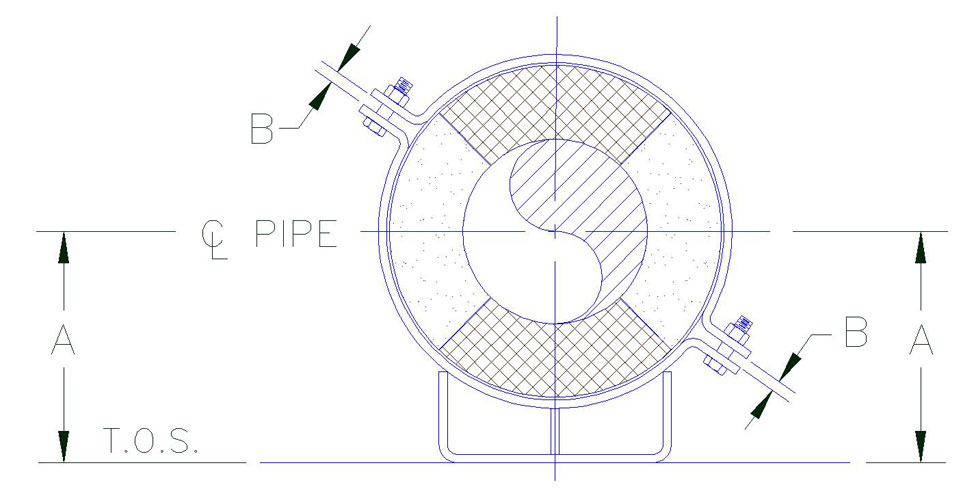

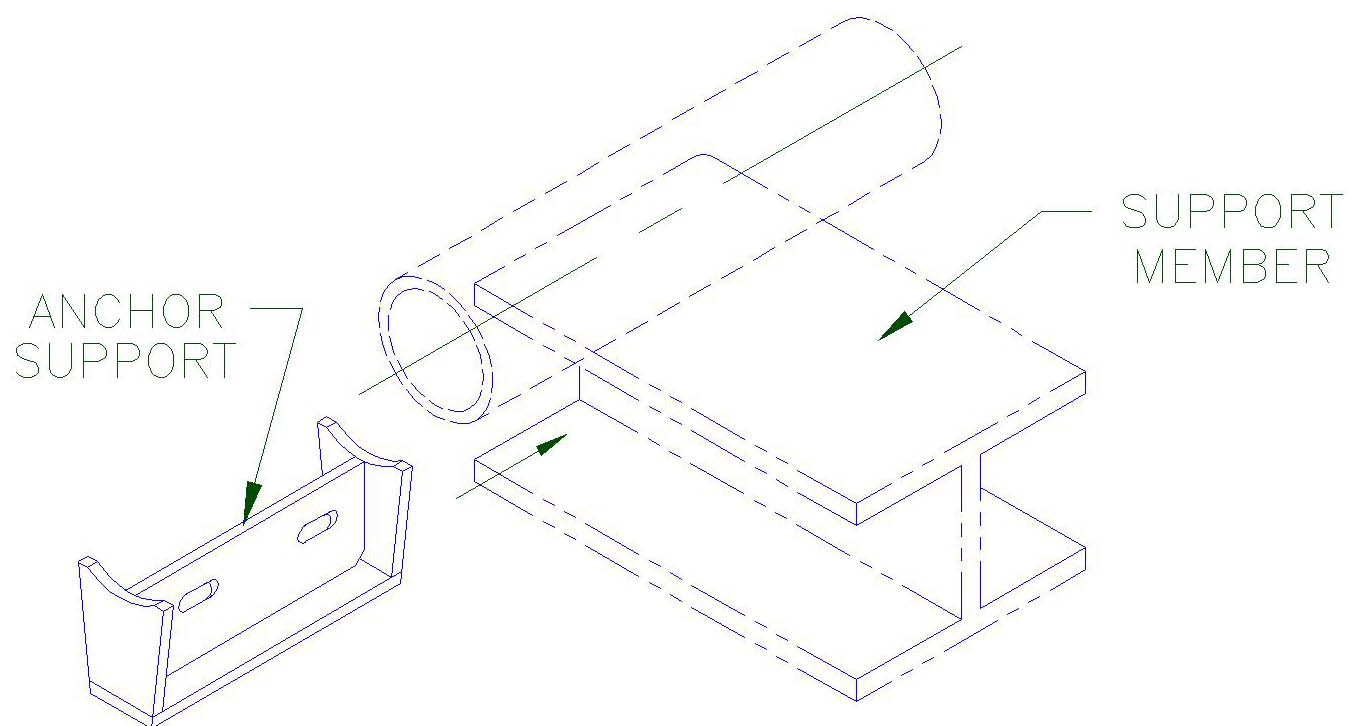

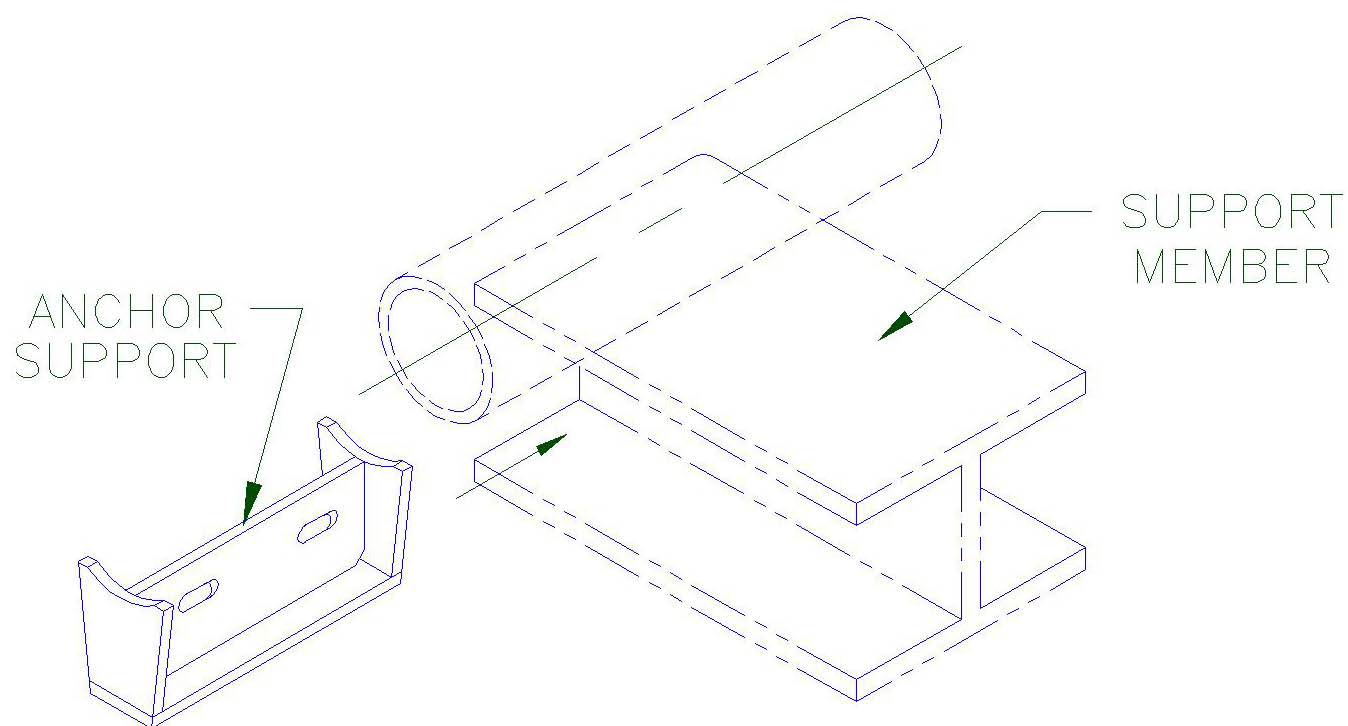

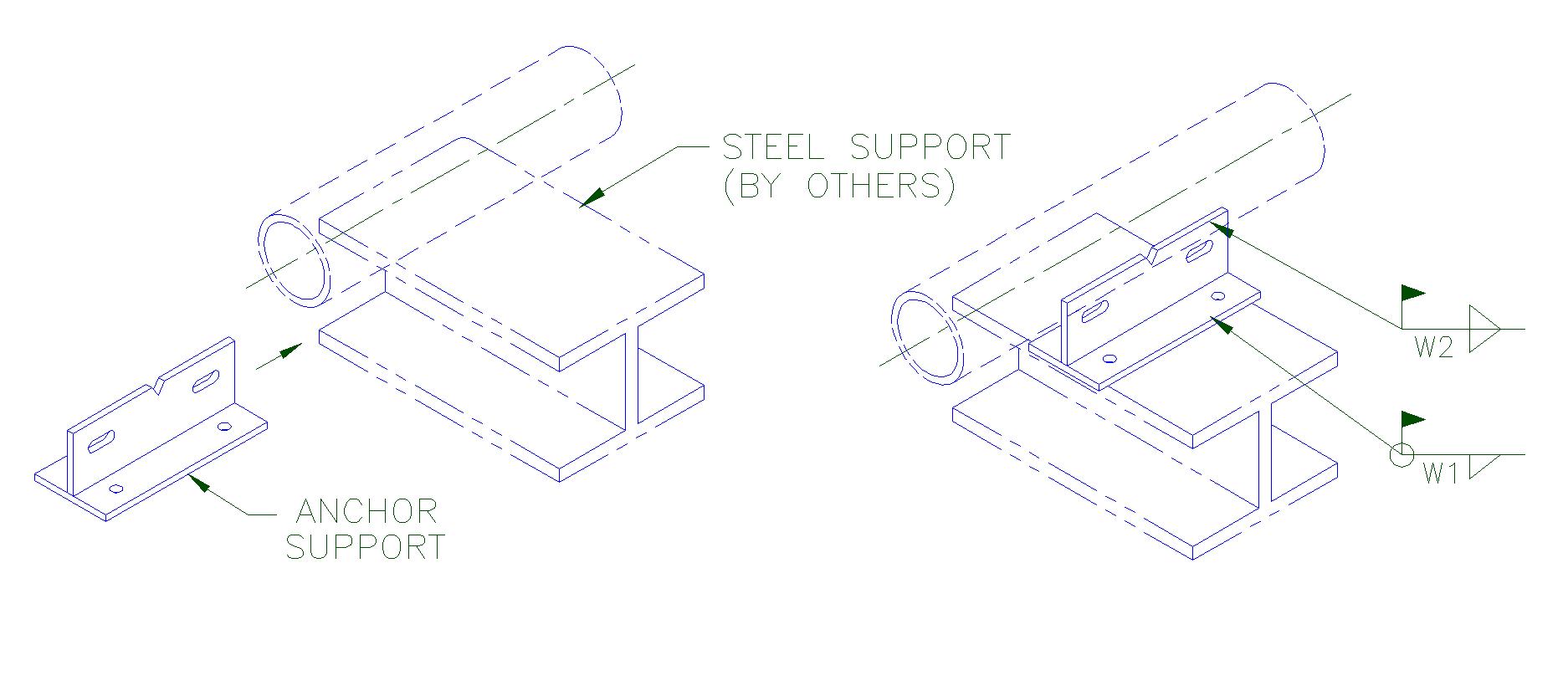

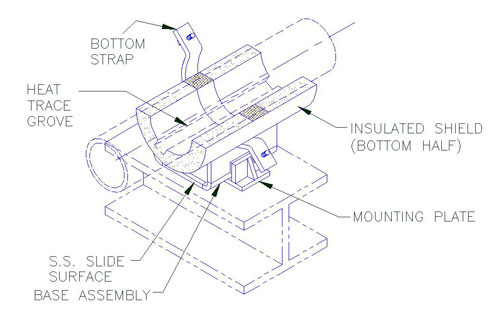

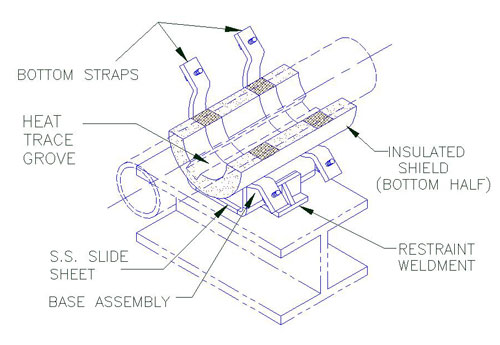

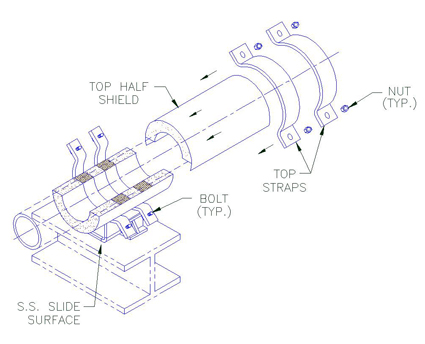

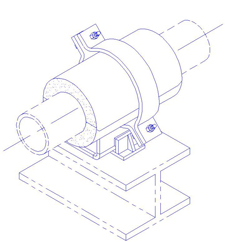

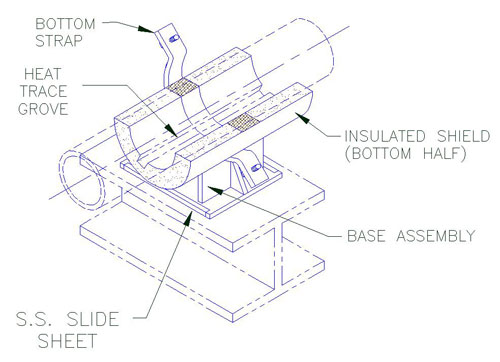

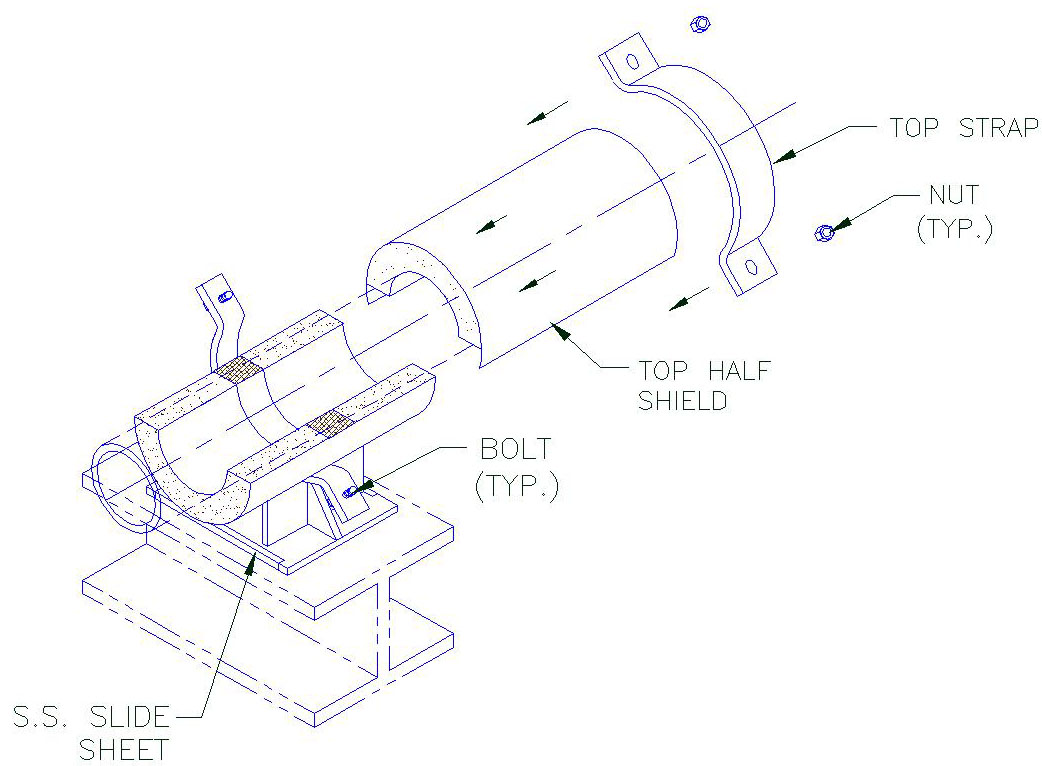

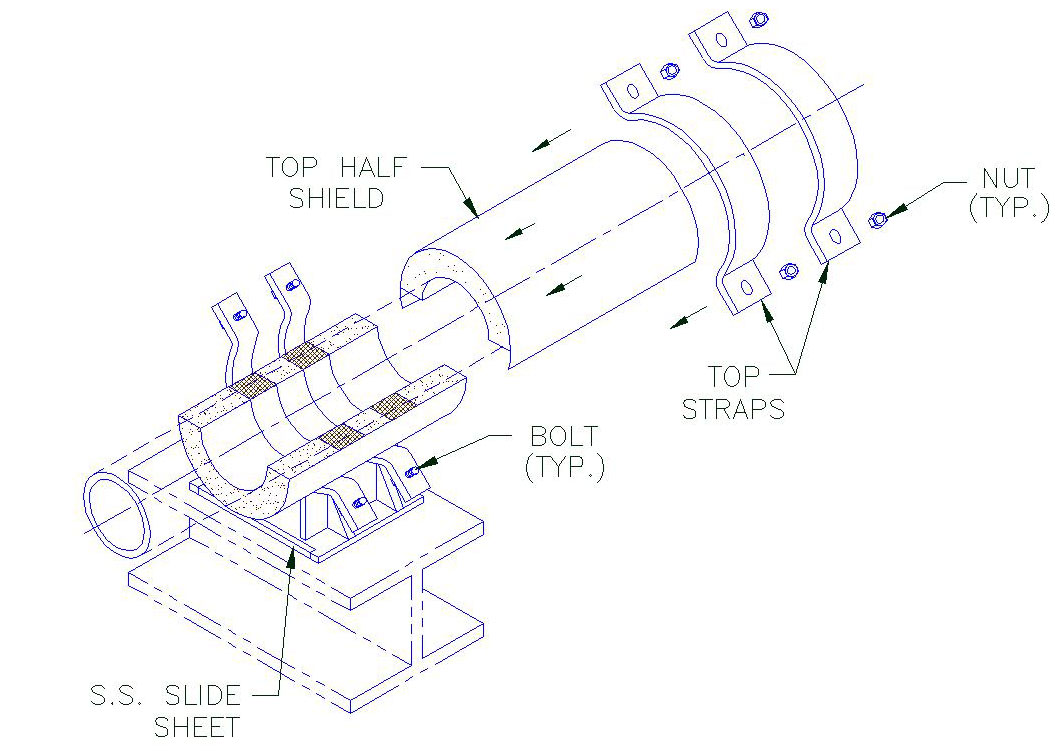

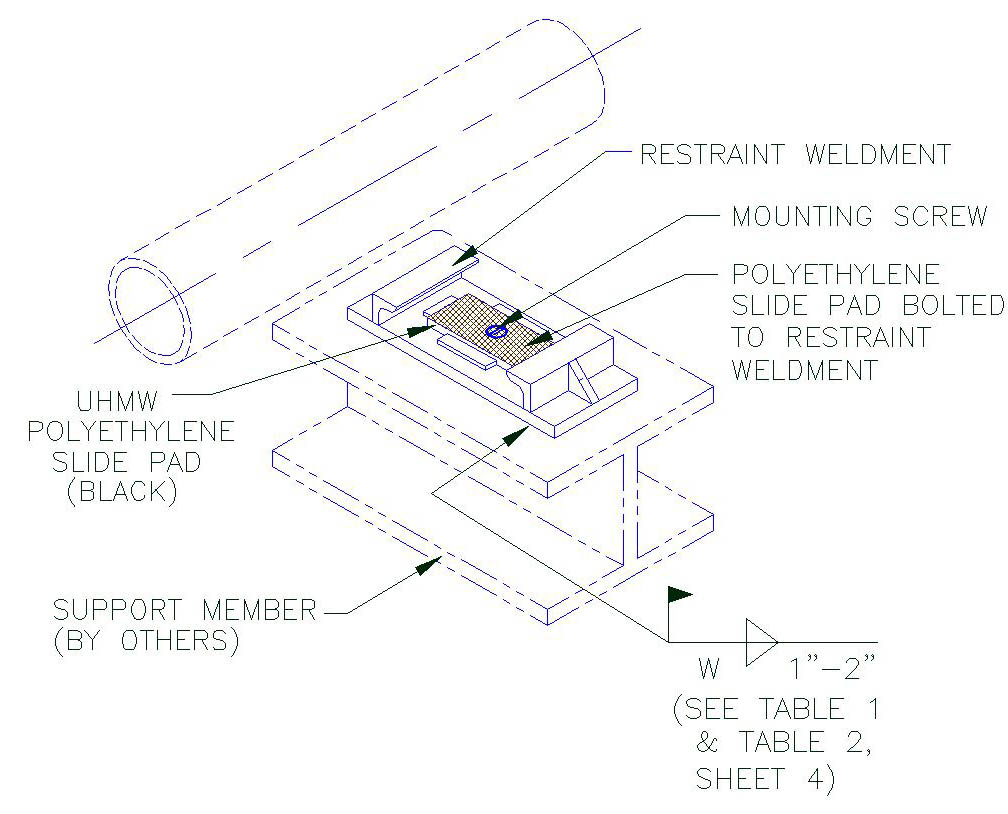

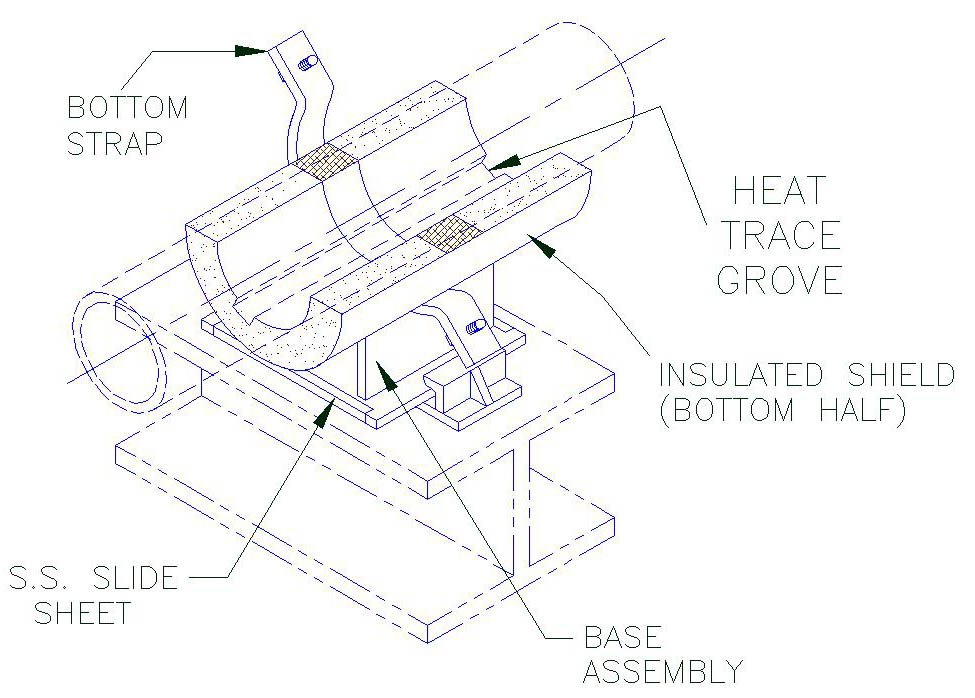

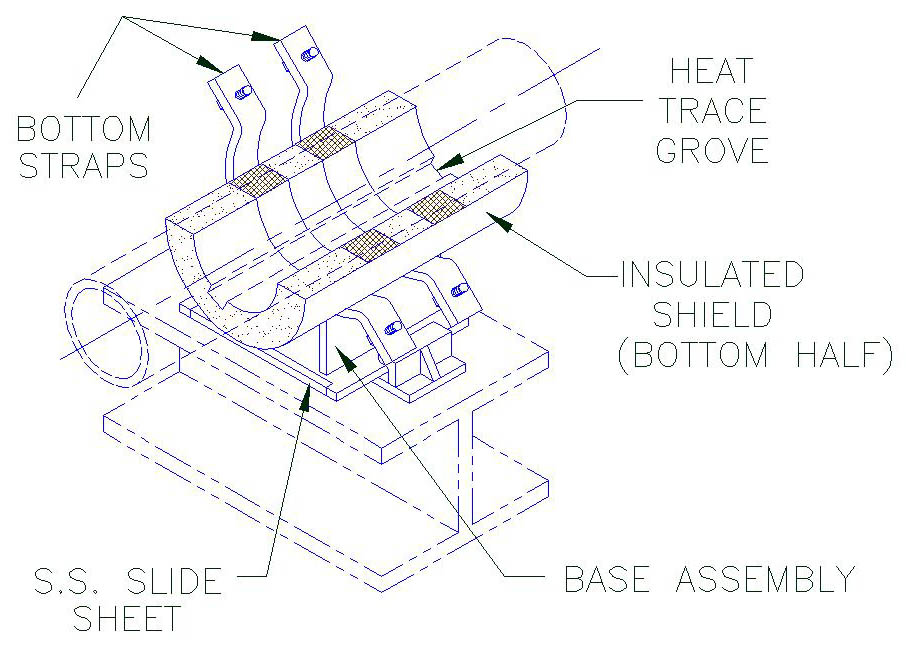

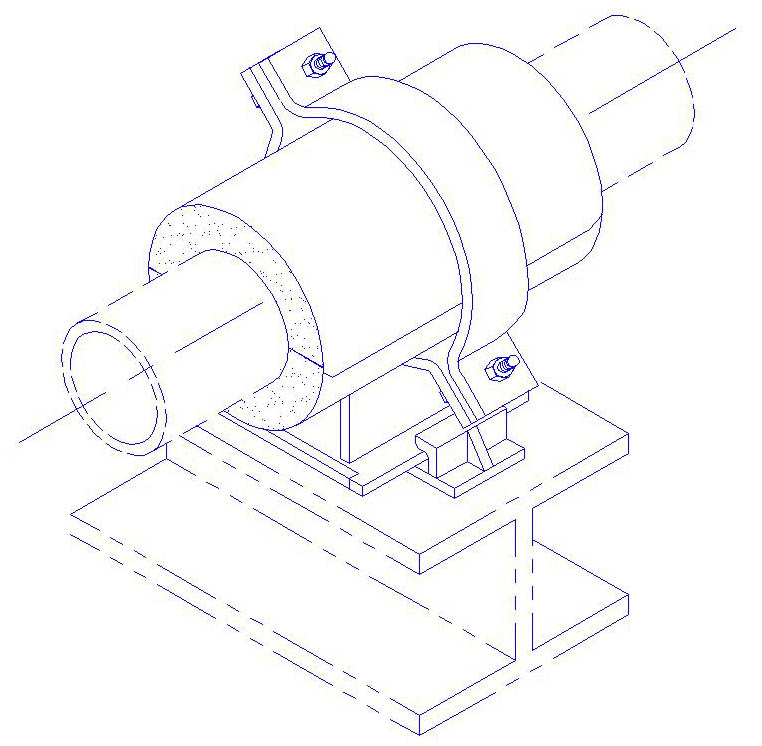

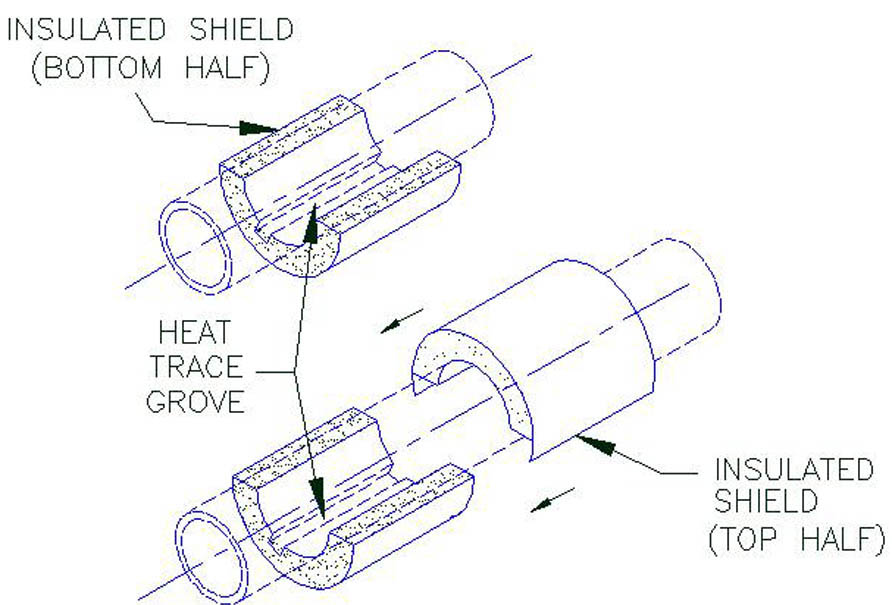

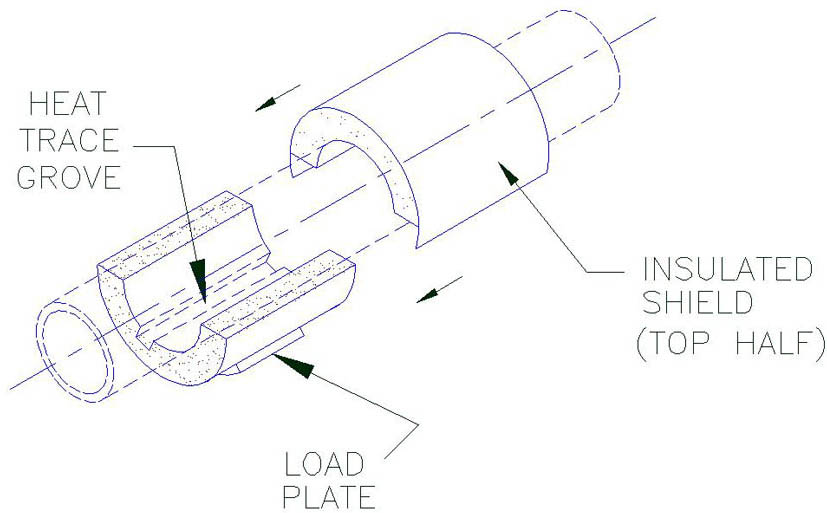

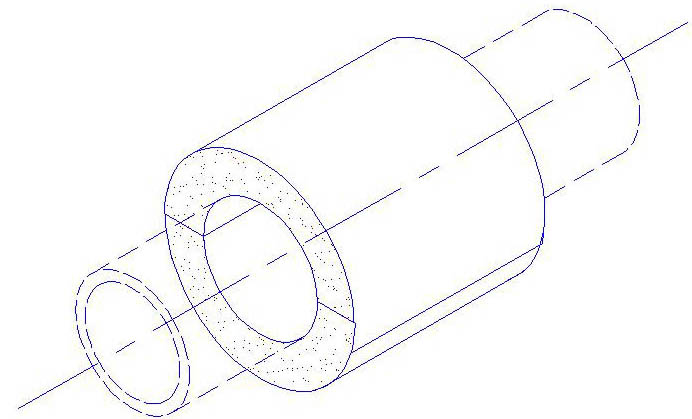

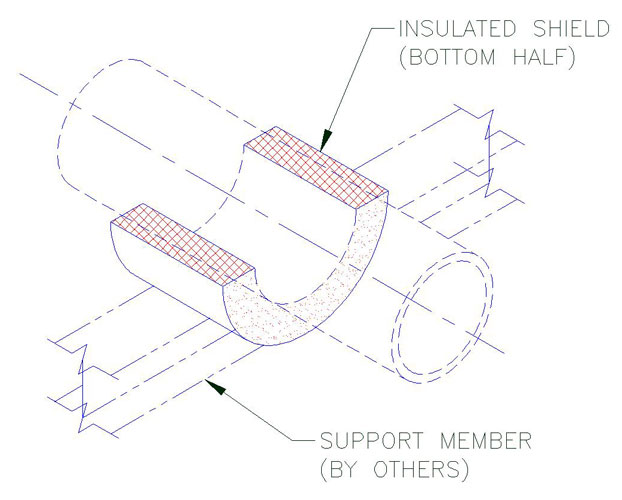

1. A) Position the bottom half of the insulated shield (insulating structural material, sheet metal jacket and load plate) on the pipe at the applicable support location as shown.

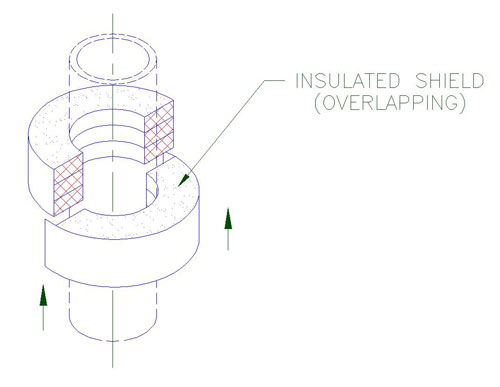

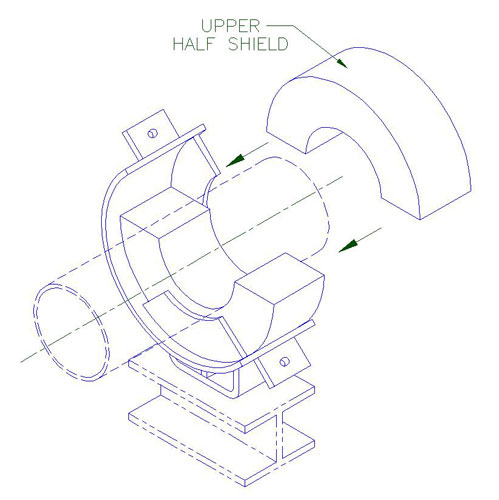

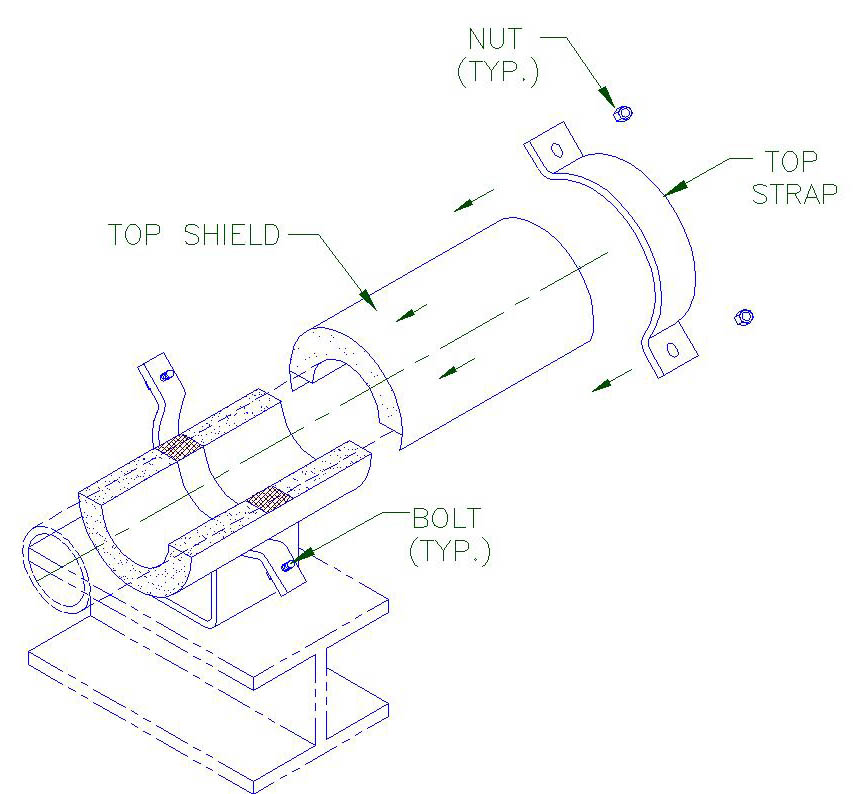

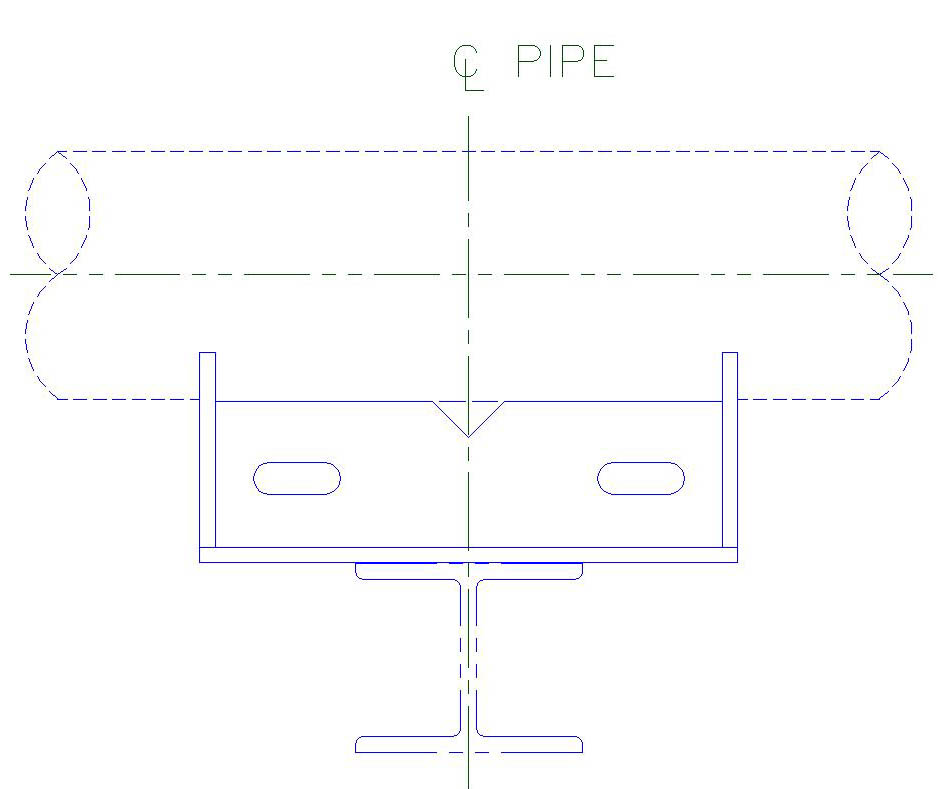

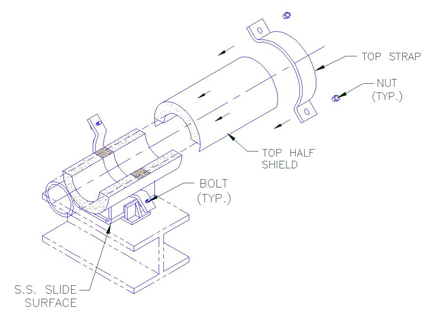

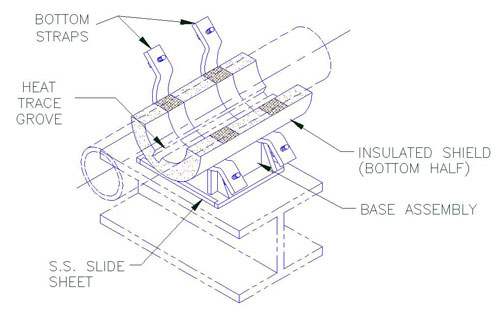

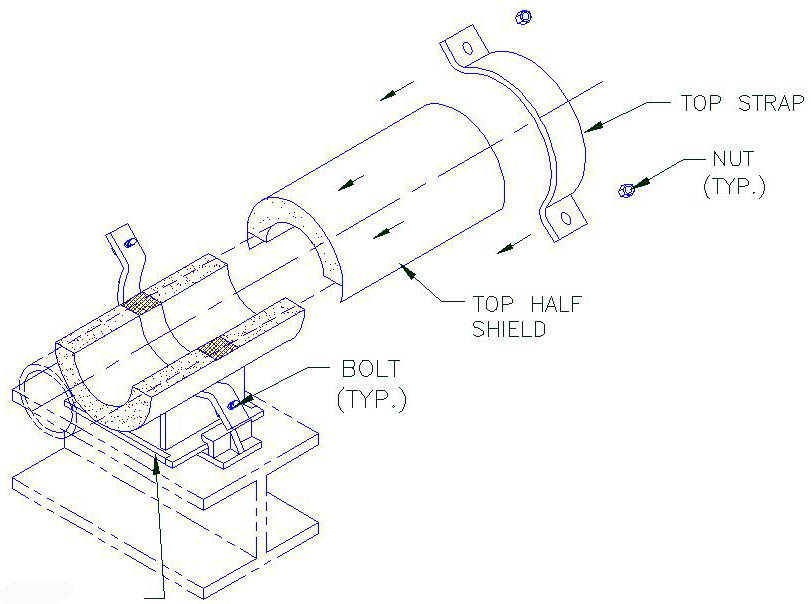

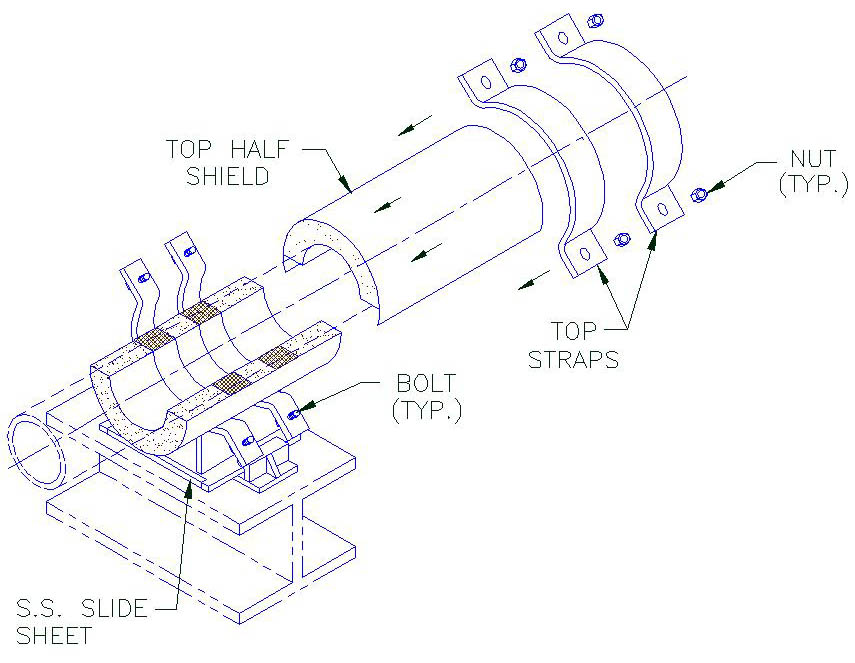

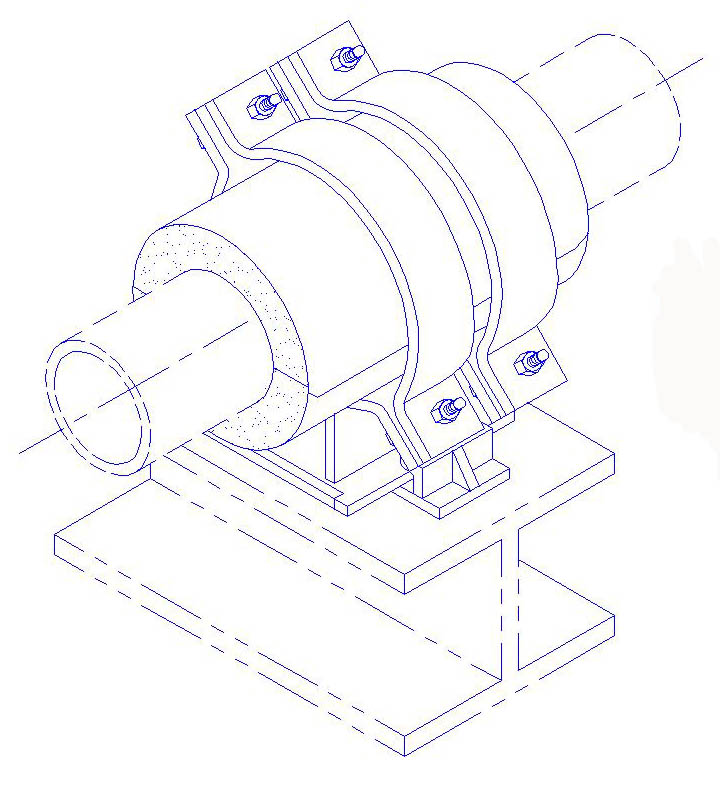

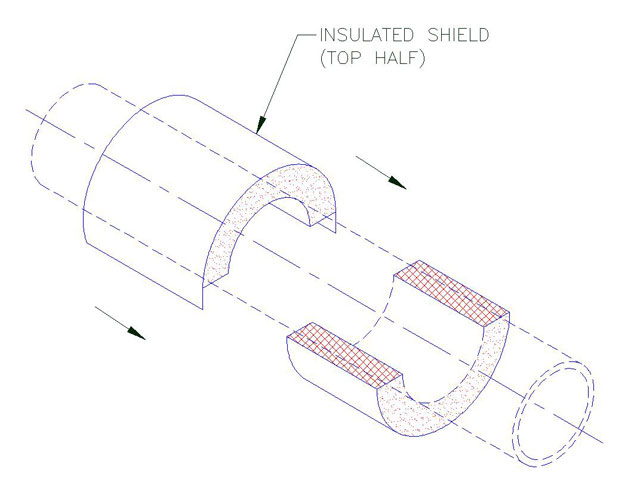

2. A) Hold firmly the top half of the shield, open the overlapping sheet metal jacket and gently slide into position the top half of the insulated shield over the bottom half-shield as shown.

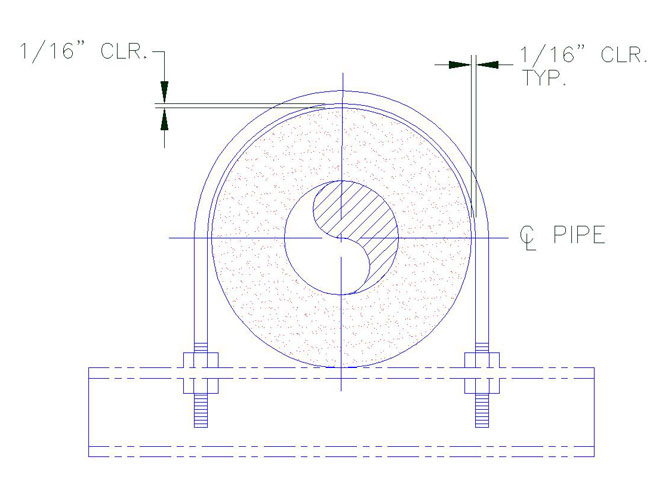

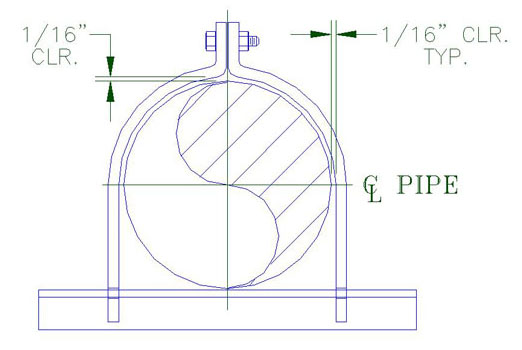

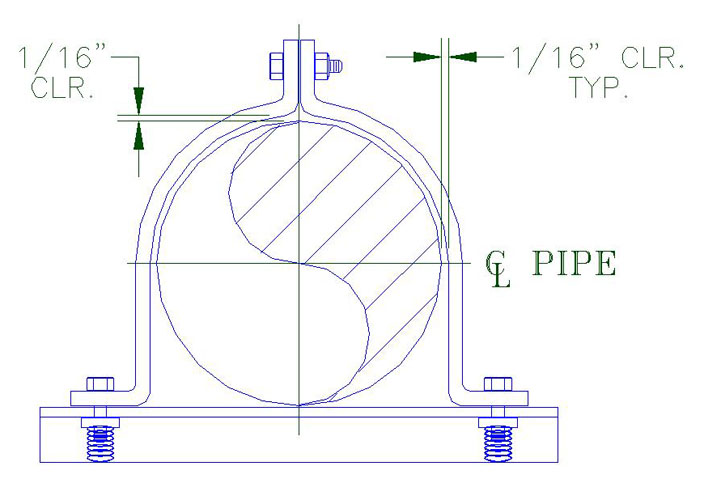

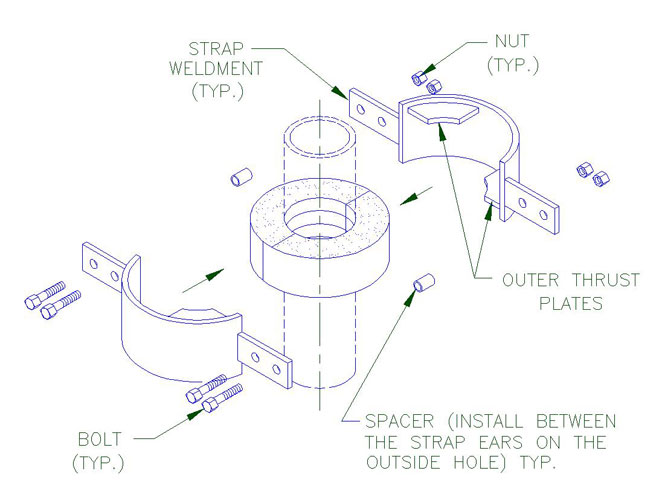

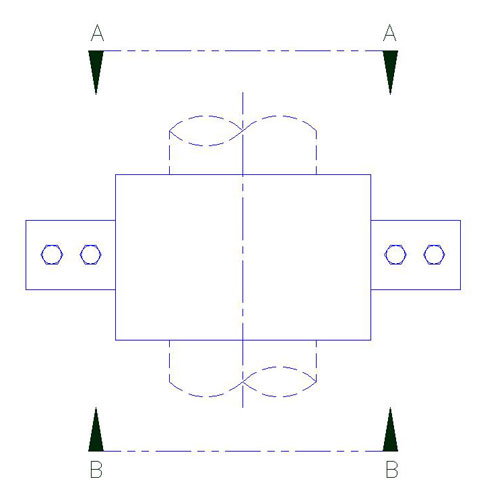

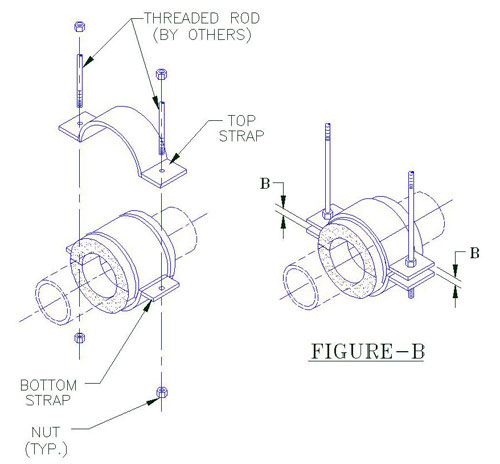

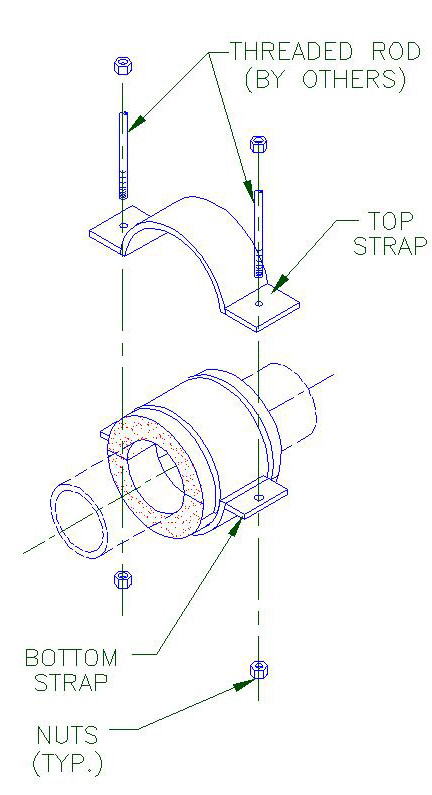

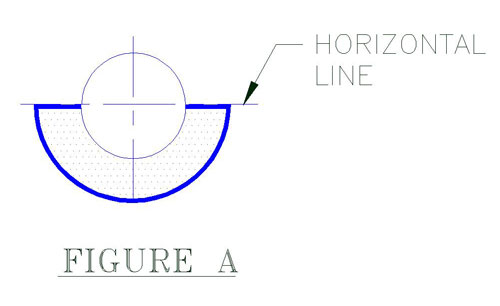

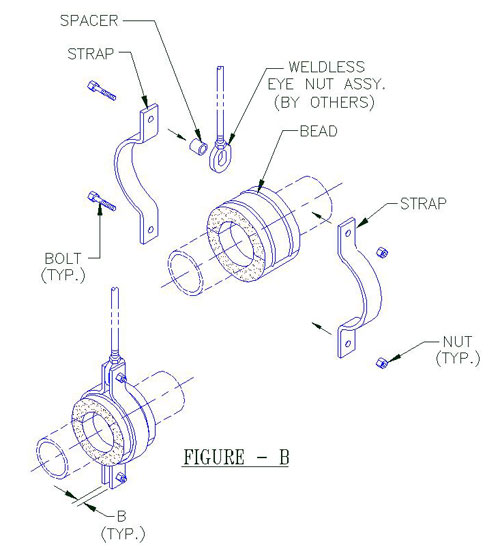

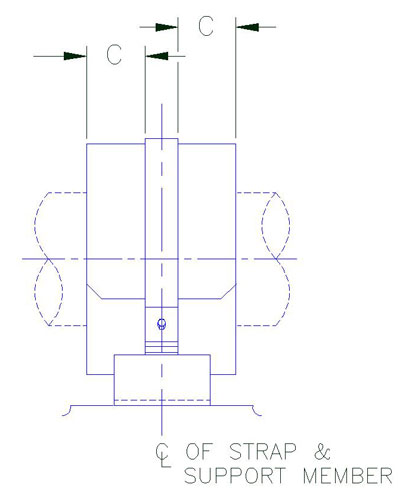

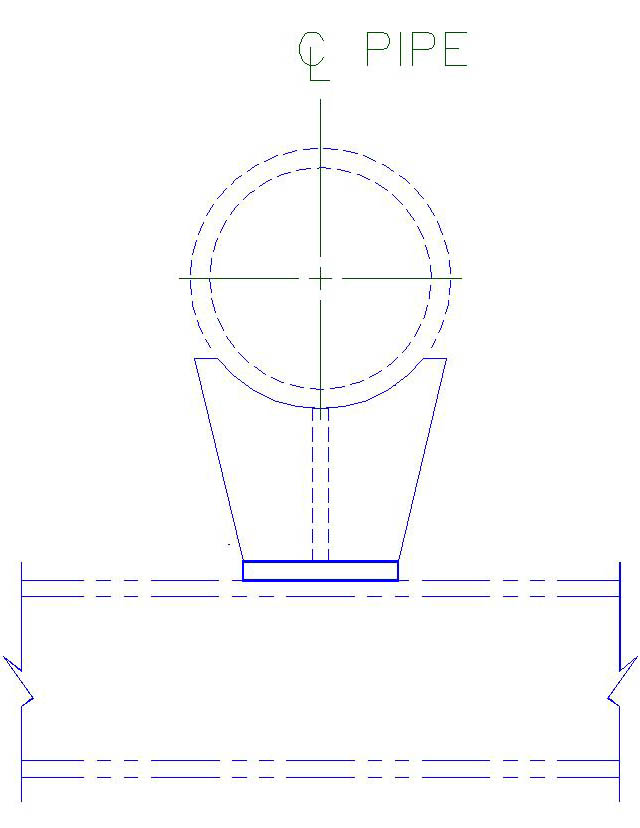

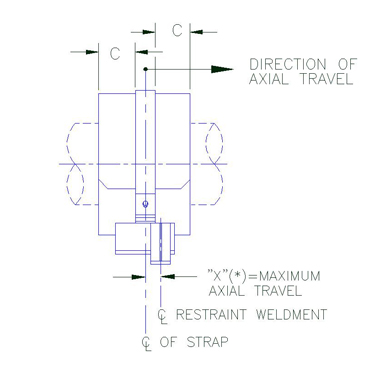

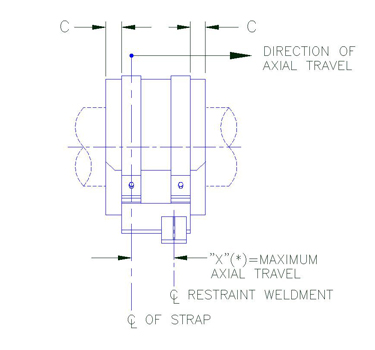

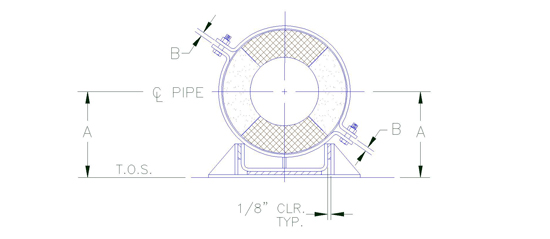

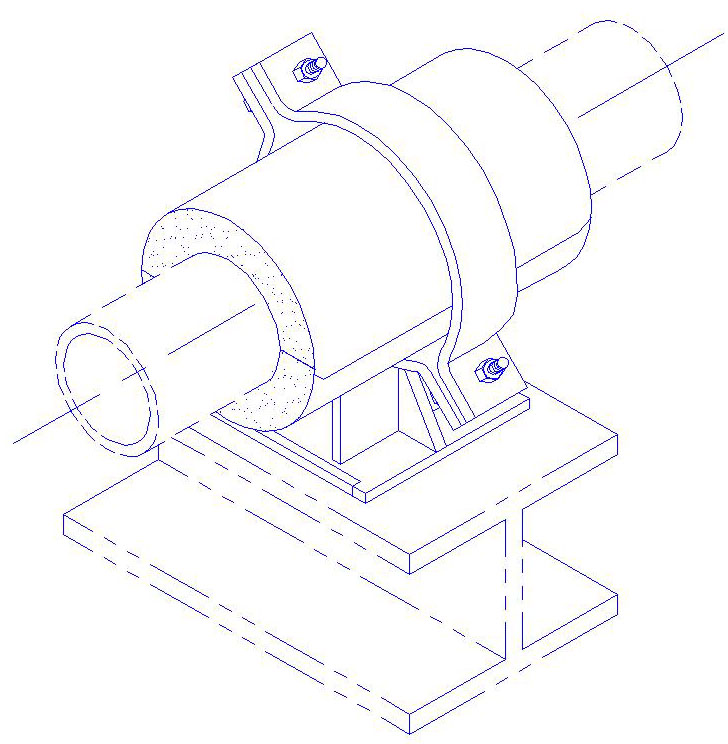

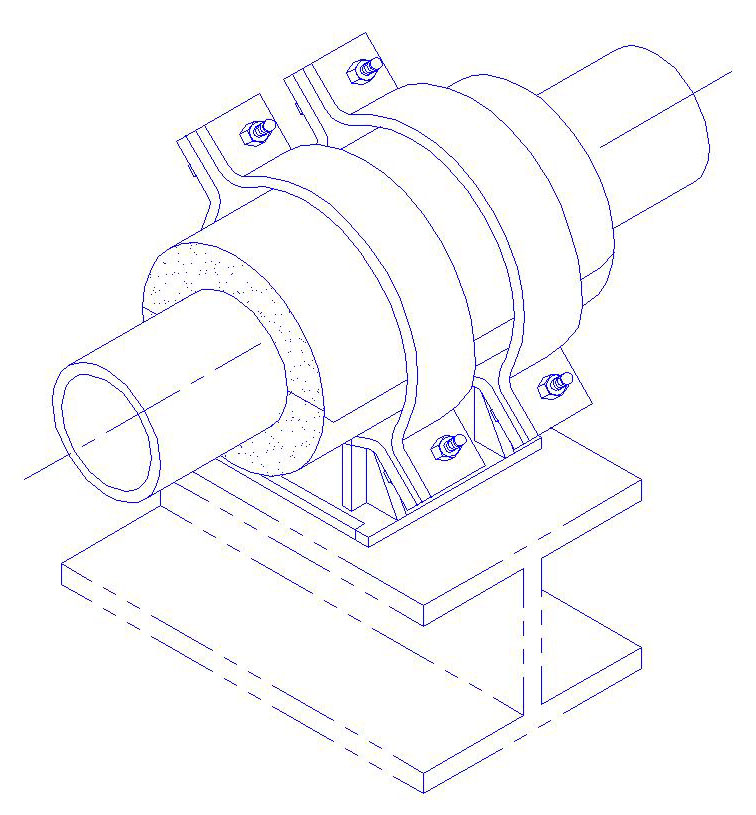

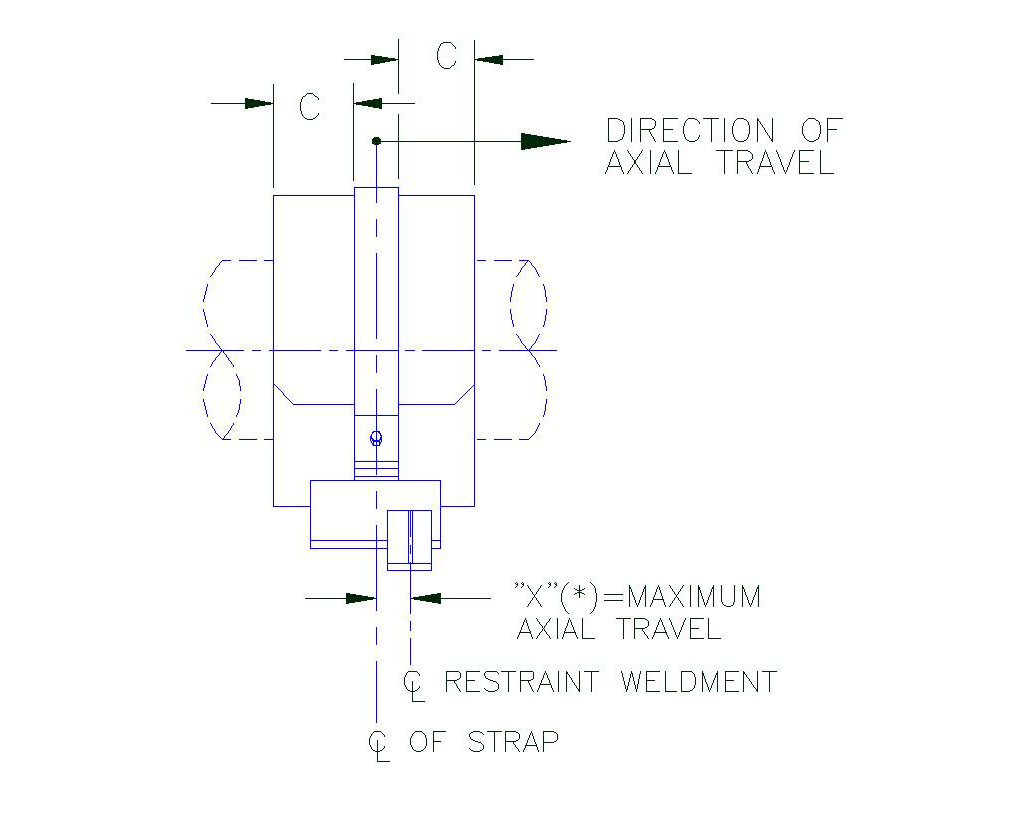

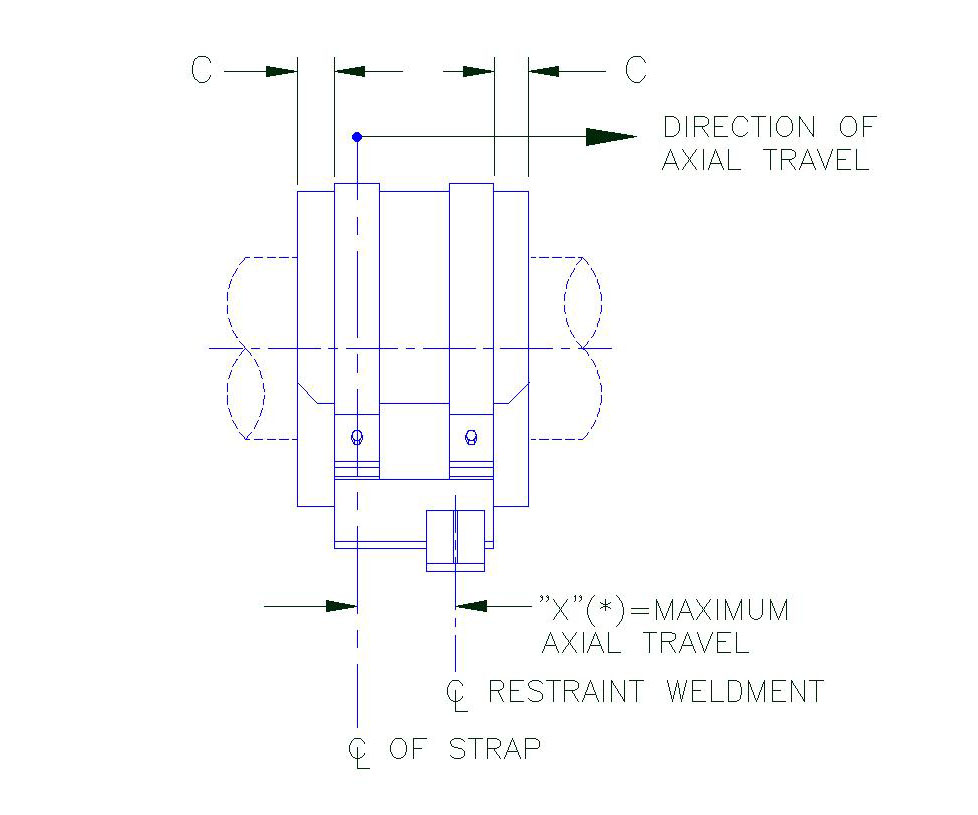

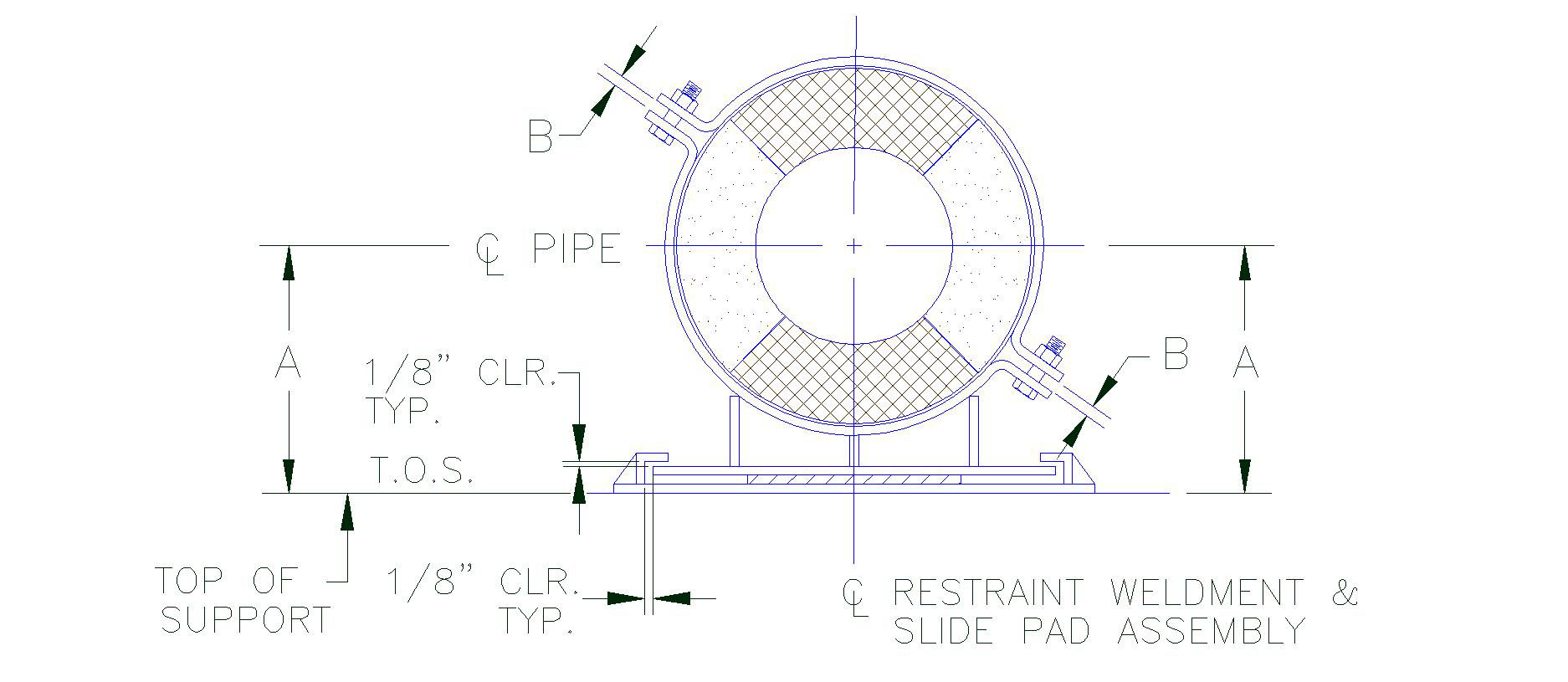

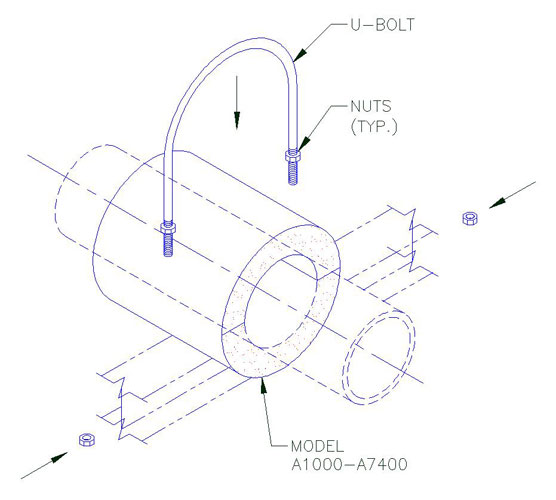

3. A) Position the U-Bolt at the appropriate location as shown.

B) Install the nuts and hand tighten until snug tight.

Note:

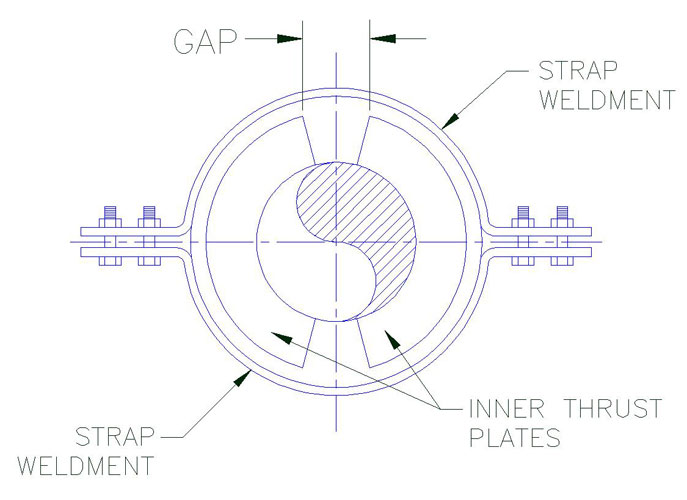

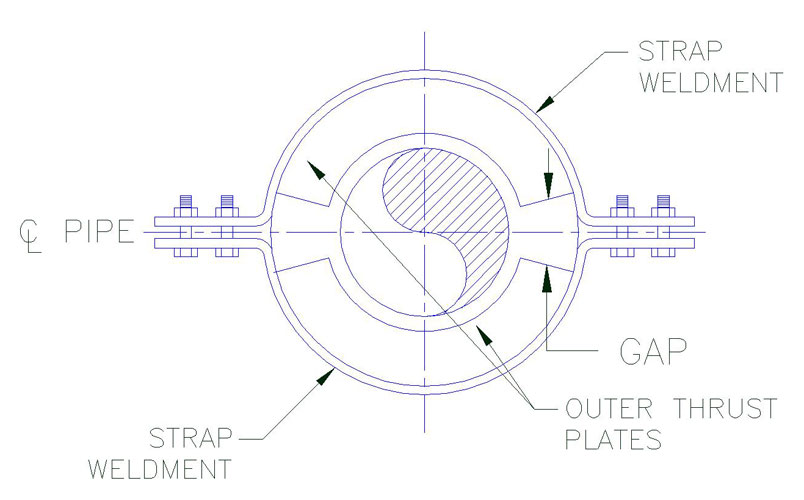

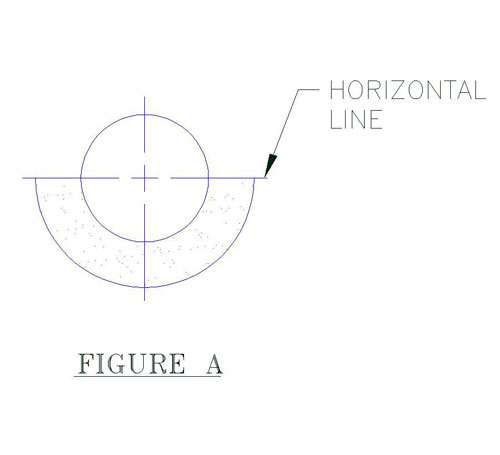

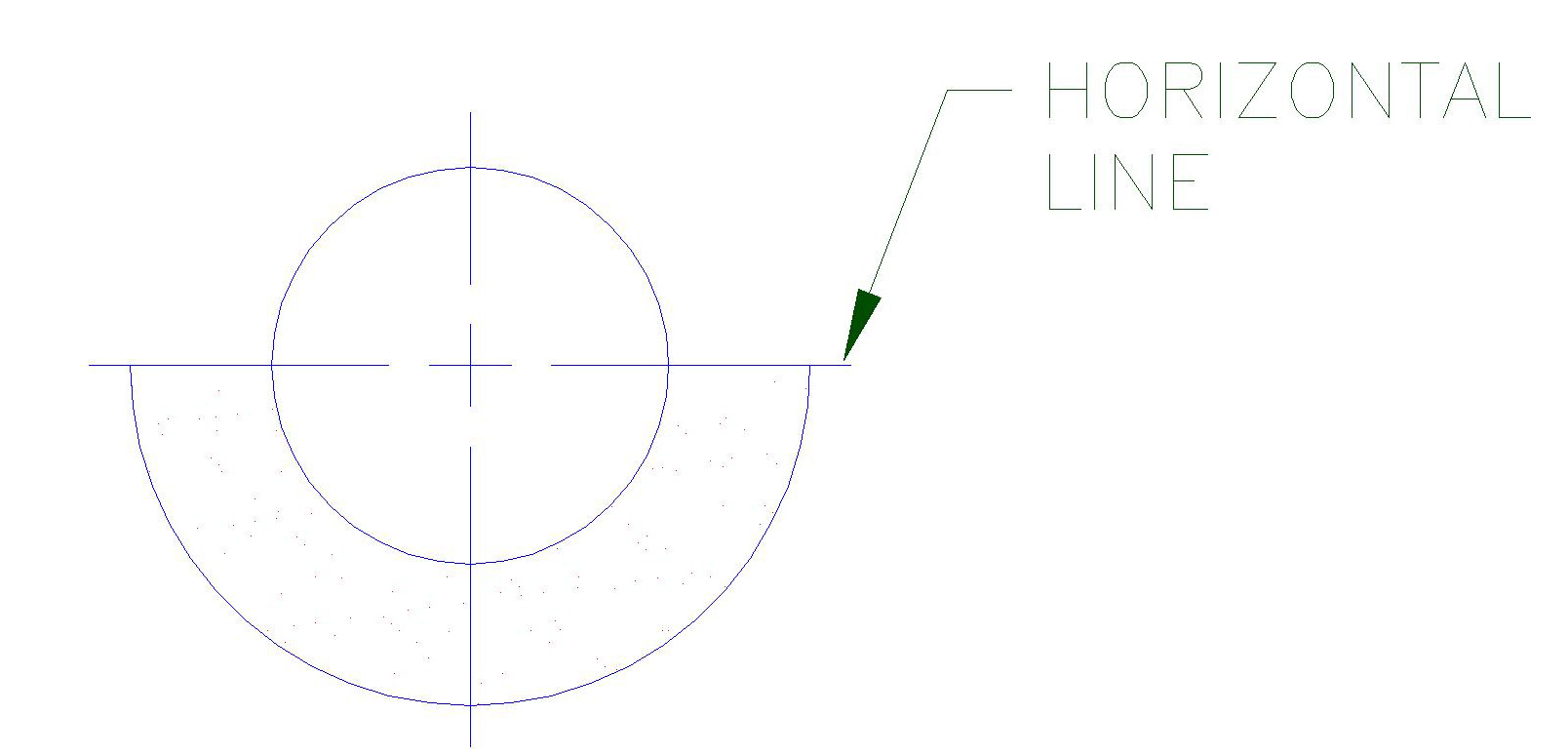

Provide 1/16″ radial clearance all around between the shield and the U-Bolt except at the bottom as shown in Figure 1.