26″ Hot Water Expansion Tank

– Material: .25″ Thick Carbon Steel

– Design Pressure: 50 PSIG

– Design Temperature: 200 F

– Capacity: 170 Gallons

Do you require a vessel or tank for your current or upcoming job? Get pricing today!

Blog Category: ASME/MISCELLANEOUS FABRICATION

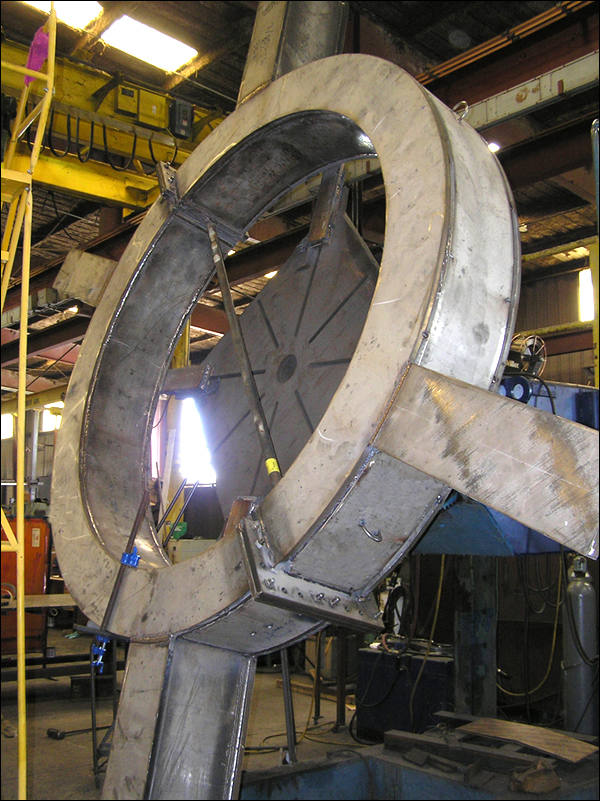

Transition Piece for an Ammonia Plant

SWECO Fab, Inc. designed and fabricated this transition piece for an ammonia plant in Egypt. The bottom rectangular flange measures 159″ long and 60″ wide. The top duct assembly has an outside diameter of 90″. The entire assembly measures 48″ high. The transition piece is fabricated from ASTM A516-70 carbon steel. It is used to connect a circular duct to a rectangular duct.

Want to learn more about the miscellaneous products we fabricate? Watch a Sweco webinar today!

58" Floating Rings for High Temperatures of up to 1200°F

58″ Floating Rings for a Process Plant

– Sizes Range from 19″ I.D. to 91 1/2″ I.D.

– ASTM A-240 Grade 316H Stainless Steel

– 100% Dye Penetrant Tested on all Weld Seams

Want to learn more about the miscellaneous fabricated products we supply? Watch a webinar today!

90" O.D. Duct Work for an Ammonia Plant

The duct work has an outside diameter of 90 inches and is 38 feet long. The duct assembly is fabricated entirely from ASTM A516-70 carbon steel. The assembly has two support bases and stiffening rings that provide strength and rigidity for the duct work. The assembly is a section of air supply duct in an Ammonia Plant.

Do you require duct work for your piping system? Get pricing today!

7 Foot Long Pressure Vessel for a Chemical Plant

This pressure vessel measures 84″ in length and is fabricated entirely of SA516-70 carbon steel. It is designed for low temperature environments and has a design pressure of 117 PSIG at 500ºF. A hydrostatic test was completed at 205 PSIG prior to shipment.

Do you have a requirement for a pressure vessel in your plant? Get pricing today!

48" Carbon Steel Pressure Vessel

Pressure Vessel

– Diameter: 48″ O.D.

– Capacity: 1,100 Gallons

– Material Fabricated From: Carbon Steel

– Design Temperature & Pressure: 285 PSIG at 100ºF

– Testing: Hydro-Tested and held for 1/2 hour at 428 PSIG

Do you have a need for a pressure vessel? Get pricing on a vessel today!

Pig Launchers/Receivers for a Petroleum Pipeline

The three pig launchers measure 127″, 172″, and 189″ in length and are designed for 263 PSIG at 185ºF. The pipe diameters of each unit measure 10″, 18″, and 20″, respectively. Two of the pig launchers/receivers are fabricated from carbon steel and one from stainless steel. All of the launchers/receivers were hydro-tested to ensure product quality.

Do you see a need for pig launchers in your piping system? Get pricing today!

ASME Code Pressure Vessels

These molecular sieve vessels are designed for a biofuel production line. They are fabricated from stainless steel with carbon steel base rings. The vessels have an outside diameter of 24″ and measures 214″ in length. The maximum allowable working pressure is 123 PSIG @ 400ºF. These ASME Code pressure vessels were hydro-tested at 160 PSIG and x-ray tested prior to being shipped to the customer.

Do you require ASME pressure vessels or tanks? Let us price them for you today!

Exhaust Manifold that will be used with an Electric Generating System

This engine exhaust duct spool is fabricated from carbon steel and coated with specialized paint that is capable of resisting temperatures up to 1,000ºF. It measures 6′ long and connects two exhaust manifolds of 18″ in diameter to a bottom flange of 50″ in diameter. This engine exhaust duct spool will be covered with insulation and will be used to direct engine exhaust in a gas storage facility.

Want to learn more about our miscellaneous fabricated products? Watch a past webinar!

48″ I.D. ASME Code Process Vessel

This process vessel has an inside diameter of 48″ and measures 60″ tangent to tangent. The overall height of this vessel is 81″, and measures 120″ including the legs. It is fabricated from 1/2″ 516-70 carbon steel material. This vessel is designed and fabricated according to ASME Section VIII Div 1 codes. It has a capacity of 500 gallons with an internal design pressure of 50 PSIG. The maximum acceptable working pressure is 178 PSIG. This process vessel was heat treated for stress corrosion resistance in the field and 100% x-ray tested and hydro-tested at 231 PSIG prior to being shipped to the customer. This vessel was designed for the customer as a replacement vessel for one in the field that had already provided 20 years of service in a mildly corrosive environment.

Sweco Fab, Inc. worked with the customer to provide a vessel that was even more efficient than the previous one by including 1/8″ thicker walls, an additional 12″ between tangents, heat treatment, an internal drip plate, and an OSHA compliant ladder and platform.

Want to learn more about pressure vessels and tanks? Watch a Sweco Fab webinar now!