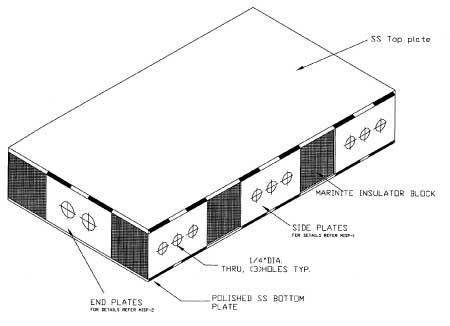

Marinite Slide Bearing Plates

Piping Technology & Product’s marinite slide bearing plates are rectangular slide-plate assemblies consisting of a marinite insulator block sandwiched between stainless steel top and bottom plates. These marinite slide bearing plates are held together by side plates along the length, and end plates along the width of the assembly.

Marinte Plates Construction

The side and end plates have 1/4″ diameter through holes and are stitch welded to the top and bottom plates. The bottom plate is polished to a mirror finish for sliding along the surface of polytetrafluoroethylene (PTFE) with minimal coefficient of friction. The assembly is generally welded to shoes.

Marinte Plates Application

The marinite insulator assembly allows the use of polytetrafluoroethylene (PTFE) as the sliding surface for lines with high operating temperatures and high dynamic loading. It protects the polytetrafluoroethylene (PTFE) by acting as a barrier to heat transfer. It has so far been used for power plants — high energy systems (SHP, SIP). It could potentially be used wherever there are movements at top, bottom or laterally at the point support.

So the benefits of having a marinite insulator include:

-

- Facilitates use of polytetrafluoroethylene (PTFE) on high-temperature lines.

- Marinite being a high load bearing insulation material is ideal for the dynamic conditions.

Marinite Plates: PT&P’s Capabilities

Piping Technology & Products is a supplier of marinite slide bearing plates, which through proven testing allows for the use of polytetrafluoroethylene (PTFE) as the sliding surface for lines, even under extremely high operating temperatures. Piping Technology & Products has supplied these plates for a number of companies in the oil, gas and power industry.