The insulated pipe support can save you money on your bid and on the job. On commercial and light industrial work, when an insulated pipe support is installed in a clevis hanger, the Insulation Contractor never touches the pipe hanger and only needs to make a simple butt joint between the pipe insulation and the insulated support. The Mechanical Contractor does not have to return for expensive, final adjustment. On heavy industrial work, on alloy steel or stainless steel pipe, there is no welding, no pre-heat or post-heat, no certified welders and no x-ray inspection required. On any type of work, if otherwise permitted, there is an insulated pipe support available which will allow you to maximize the support spacing and, thus, reduce the number of supports required on the job. The Insulation Contractor should reduce his bid to allow for labor and materials not used.

Pre-Insulated Pipe Support

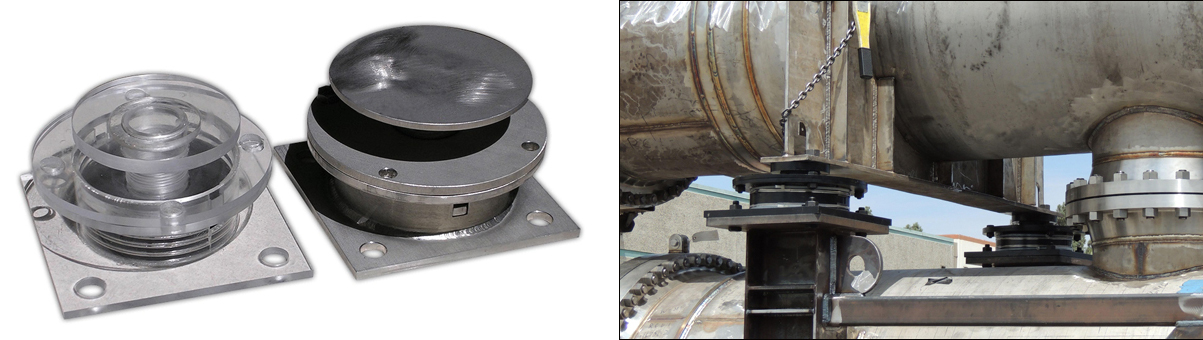

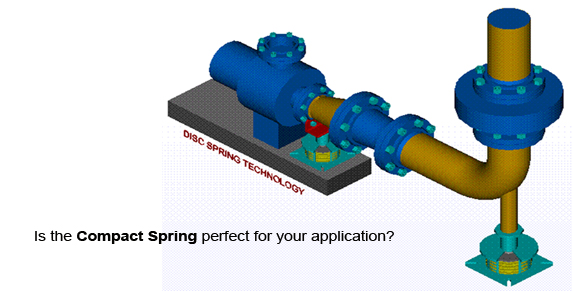

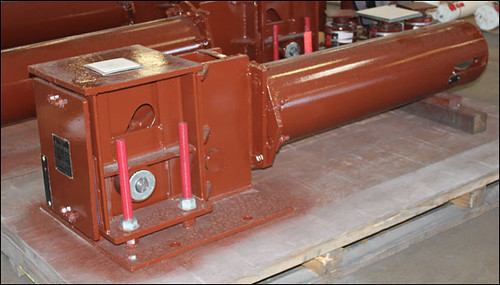

The compact spring is ideal for applications with large loads and limited space.

The compact spring is ideal for applications with large loads and limited space.